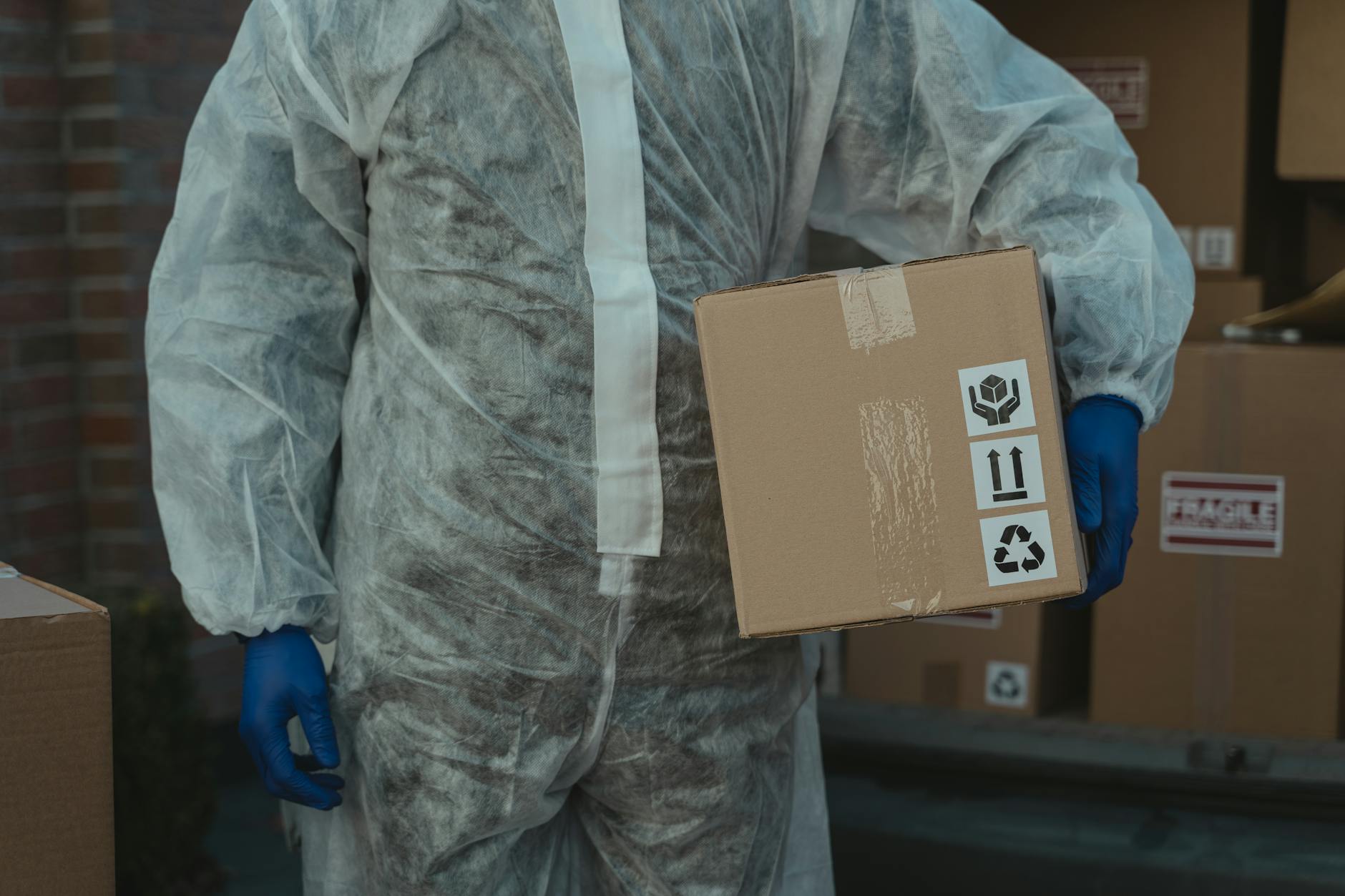

Title: Innovating Logistics: Soft Robotics – A game-changer in Fragile Goods Handling

Robotic technology continues to revolutionize various industries, and the logistics sector is no exception. With the rise in e-commerce and the demand for safe and efficient handling of fragile goods, the emergence of soft robotics has offered a transformative solution. Soft robotics, characterized by its flexibility and gentle touch, is increasingly being recognized as the best approach for safely handling delicate products in the logistics and manufacturing fields. This article explores the significance of soft robotics in the context of fragile goods handling, its applications, benefits, and the future prospects in enhancing operational efficiencies and customer satisfaction.

The Rise of Soft Robotics in Fragile Goods Handling

Soft robotics represents a breakthrough in robotics technology, offering a more adaptive and versatile alternative to traditional rigid robots. Unlike conventional rigid robots that use rigid materials like metal or plastic, soft robotics utilize soft and pliable materials inspired by natural organisms such as octopuses and caterpillars. This unique design allows soft robots to mimic the human hand’s dexterity and sensitivity, making them ideal for tasks that require gentle interaction, such as handling fragile goods.

Applications of Soft Robotics in Fragile Goods Handling

One of the primary applications of soft robotics in logistics is in the handling of fragile goods. Products such as electronic components, glassware, medical devices, and food items require delicate care during the transportation and handling process to prevent damage. Soft robots equipped with advanced sensors and actuators can adjust their grip and pressure levels based on the object’s fragility, ensuring a secure yet gentle hold during pick-and-place operations. This precision and adaptability make soft robotics a preferred choice for tasks that demand high levels of accuracy and safety.

Benefits of Soft Robotics for Fragile Goods Handling

The adoption of soft robotics in fragile goods handling offers several key benefits for companies operating in the logistics and manufacturing sectors. One of the primary advantages is improved product safety and reduced damage rates. Soft robots’ compliant nature allows them to absorb impacts and vibrations, minimizing the risk of accidental drops or collisions that can result in product breakage. By enhancing product safety, companies can lower loss rates, improve customer satisfaction, and reduce costly returns.

Furthermore, soft robotics can enhance operational efficiency by accelerating handling processes and reducing manual labor requirements. Soft robots can perform intricate movements with precision and speed, increasing throughput rates and overall productivity. This not only streamlines logistics operations but also minimizes the risk of human error, resulting in higher accuracy and consistency in fragile goods handling tasks.

Future Prospects and Innovations in Soft Robotics

As the demand for safe and efficient handling of fragile goods continues to grow, the future outlook for soft robotics in logistics appears promising. Researchers and engineers are continually exploring new innovations to enhance soft robots’ capabilities, such as integrating machine learning algorithms for improved object recognition and adaptive grasping strategies. Additionally, advancements in soft materials and sensor technologies are enabling the development of more sophisticated soft robotic systems that can handle a wider range of fragile objects with varying shapes and sizes.

In conclusion, soft robotics represents a groundbreaking solution for safely handling fragile goods in the logistics and manufacturing industries. Its flexibility, precision, and adaptability make it an ideal choice for tasks that require delicate interaction with fragile products. By leveraging soft robotics technology, companies can enhance product safety, improve operational efficiency, and deliver a superior customer experience. As soft robotics continues to evolve and innovate, it is poised to play a significant role in shaping the future of logistics and supply chain management.

In essence, the integration of soft robotics in fragile goods handling signifies a paradigm shift towards a more efficient, reliable, and sustainable approach to logistics operations.