- Importance of Robotics Safety Standards

- Understanding ISO 10218: Robotics Safety Requirements

- Implementing Risk Assessment Procedures

- Safe Human-Robot Collaboration

- Compliance with Functional Safety Standards

- Training and Education for Workers

- Continuous Monitoring and Evaluation

- Conclusion

With the rapid advancements in technology, robotics has become an integral part of modern manufacturing processes. While robotic systems offer numerous benefits such as increased productivity, efficiency, and precision, ensuring the safety of workers and equipment is paramount. Manufacturers must adhere to essential robotics safety standards to protect employees, prevent accidents, and maintain compliance with regulations. In this article, we will delve into the key safety standards that manufacturers must know to create a safe and secure working environment in a robotic manufacturing setting.

Importance of Robotics Safety Standards

Safety is a top priority in any manufacturing environment, especially when it comes to integrating robotics systems. Robotics safety standards are crucial for mitigating risks and hazards associated with automated processes. By following these standards, manufacturers can prevent workplace injuries, damage to equipment, and potential legal consequences. Adhering to safety standards also enhances overall production efficiency and reliability by minimizing downtime due to accidents or malfunctions.

Understanding ISO 10218: Robotics Safety Requirements

One of the fundamental robotics safety standards that manufacturers must be aware of is ISO 10218. This international standard outlines the general safety requirements for industrial robots and robotic systems. ISO 10218 is divided into two parts: Part 1 covers the robot itself, focusing on its mechanical integrity, electrical systems, and software, while Part 2 addresses the robot system as a whole, including tasks such as installation, programming, and maintenance.

Implementing Risk Assessment Procedures

Risk assessment plays a vital role in ensuring the safety of robotics systems in manufacturing. Manufacturers must conduct thorough risk assessments to identify potential hazards, assess risks, and implement control measures to mitigate them. Risk assessment procedures help in determining the appropriate safety measures, protective equipment, and training requirements for workers operating in close proximity to robots.

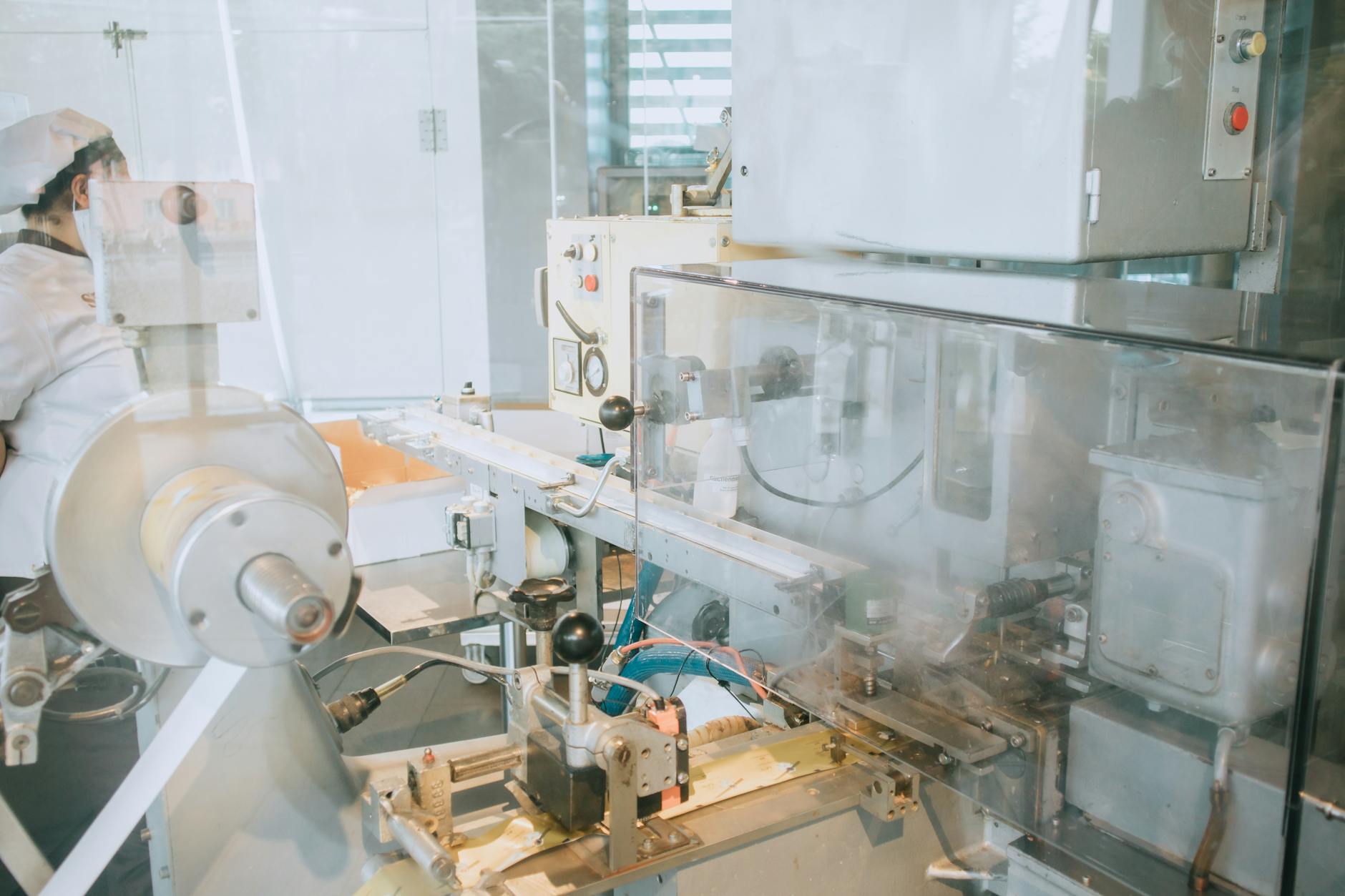

Safe Human-Robot Collaboration

In manufacturing environments where humans and robots work together, ensuring safe interaction is critical. Safety standards such as ISO/TS 15066 provide guidelines for establishing safe collaborative workspaces where humans can work alongside robots without compromising their well-being. Implementing safety measures such as safety-rated sensors, protective barriers, and training programs can help create a harmonious human-robot collaborative environment.

Compliance with Functional Safety Standards

Functional safety standards, such as ISO 13849 and IEC 62061, focus on the reliability and integrity of safety-related control systems within robotic applications. Manufacturers must design and implement safety-related control systems that meet the requirements of these standards to prevent accidents and ensure the safe operation of robotic equipment. Compliance with functional safety standards is essential for reducing the likelihood of system failures that could lead to hazardous situations.

Training and Education for Workers

Proper training and education are key components of a successful robotics safety program. Manufacturers should provide comprehensive training programs for workers involved in operating, programming, and maintaining robotics systems. Training should cover topics such as risk awareness, emergency procedures, safe programming practices, and the use of personal protective equipment. Well-trained employees are better equipped to identify potential safety risks, respond to emergencies, and contribute to a culture of safety in the workplace.

Continuous Monitoring and Evaluation

Safety standards compliance is an ongoing process that requires continuous monitoring and evaluation. Manufacturers should regularly assess the effectiveness of safety measures, identify areas for improvement, and implement corrective actions as needed. By establishing a system for monitoring safety performance and conducting regular audits, manufacturers can ensure compliance with safety standards and enhance the overall safety culture within the organization.

Conclusion

In conclusion, adherence to essential robotics safety standards is crucial for manufacturers to create a safe and secure working environment in a robotic manufacturing setting. By understanding and implementing key safety standards such as ISO 10218, conducting thorough risk assessments, promoting safe human-robot collaboration, complying with functional safety standards, providing training for workers, and continuously monitoring safety performance, manufacturers can enhance workplace safety, prevent accidents, and safeguard the well-being of employees. Prioritizing robotics safety not only protects human lives but also contributes to the long-term success and sustainability of manufacturing operations.