- The Role of AI in UK Manufacturing

- AI-Powered Robotics and Automation

- Smart Factories of the Future

- Predictive Maintenance and Quality Control

- Supply Chain Optimization

- Overcoming Challenges and Embracing Opportunities

Artificial Intelligence (AI) Revolutionizes UK Manufacturing in 2025: Cutting-Edge Innovations

The manufacturing industry in the UK is undergoing a significant transformation with the integration of Artificial Intelligence (AI) technologies. These cutting-edge innovations are reshaping traditional manufacturing processes, leading to increased efficiency, precision, and productivity. In 2025, AI is set to revolutionize the UK manufacturing sector, bringing about a new era of smart factories and advanced automation systems. Let’s delve into how AI is driving this revolution and the impact it is having on the industry.

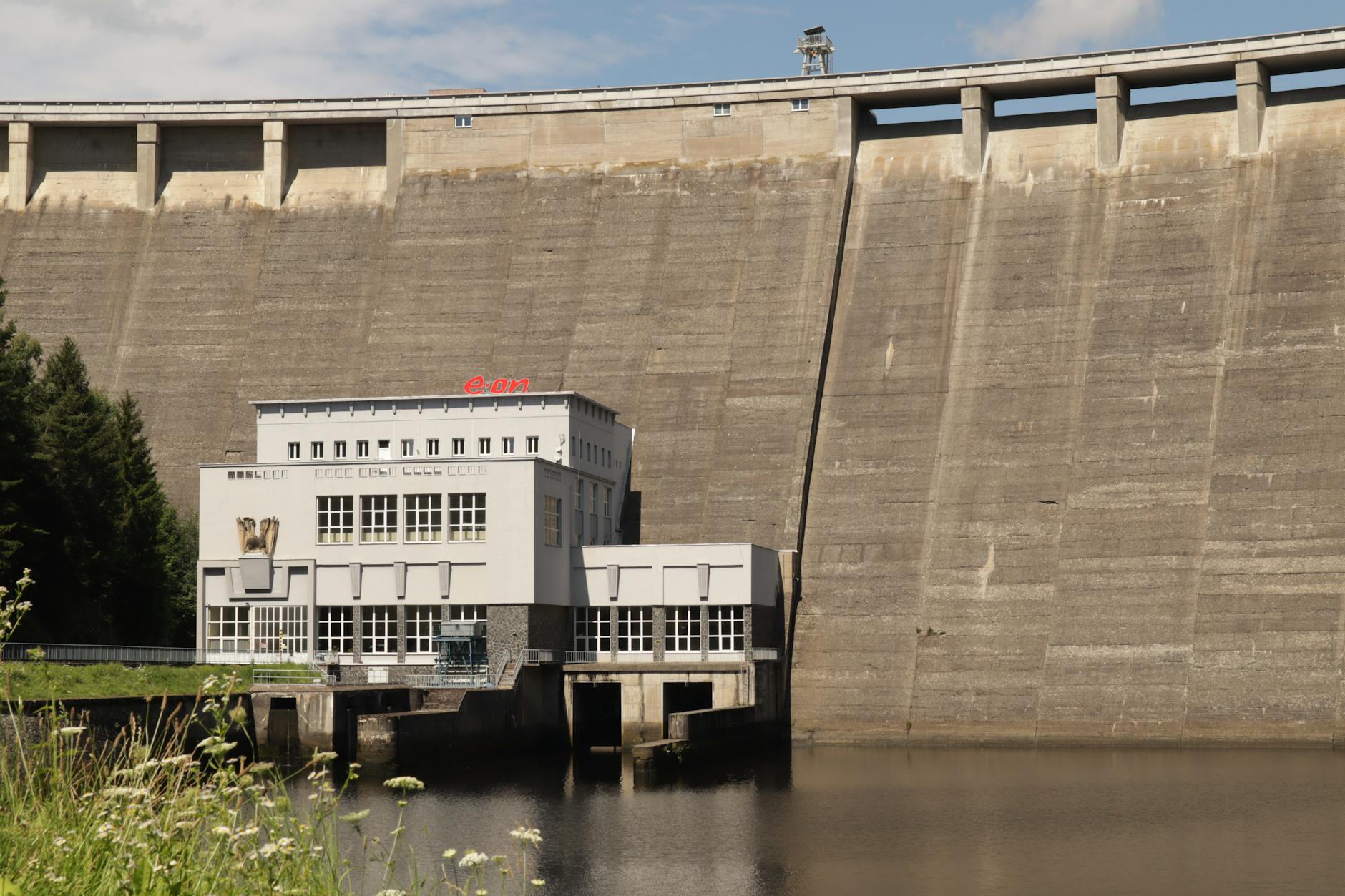

The Role of AI in UK Manufacturing

AI is playing a pivotal role in redefining the way manufacturing operations are carried out in the UK. By leveraging AI-powered algorithms and machine learning, manufacturers can optimize production processes, enhance quality control, and streamline supply chain management. AI technologies enable predictive maintenance, real-time monitoring of equipment, and personalized mass production, leading to cost savings and improved operational efficiency.

AI-Powered Robotics and Automation

One of the key areas where AI is making a significant impact is in robotics and automation. AI-powered robots are being deployed in manufacturing facilities to carry out a wide range of tasks with precision and speed. These robots can work alongside human workers, performing repetitive or dangerous tasks, thereby improving workplace safety and efficiency. With advances in machine vision and natural language processing, AI-powered robots are becoming increasingly sophisticated, enabling them to adapt to changing production environments seamlessly.

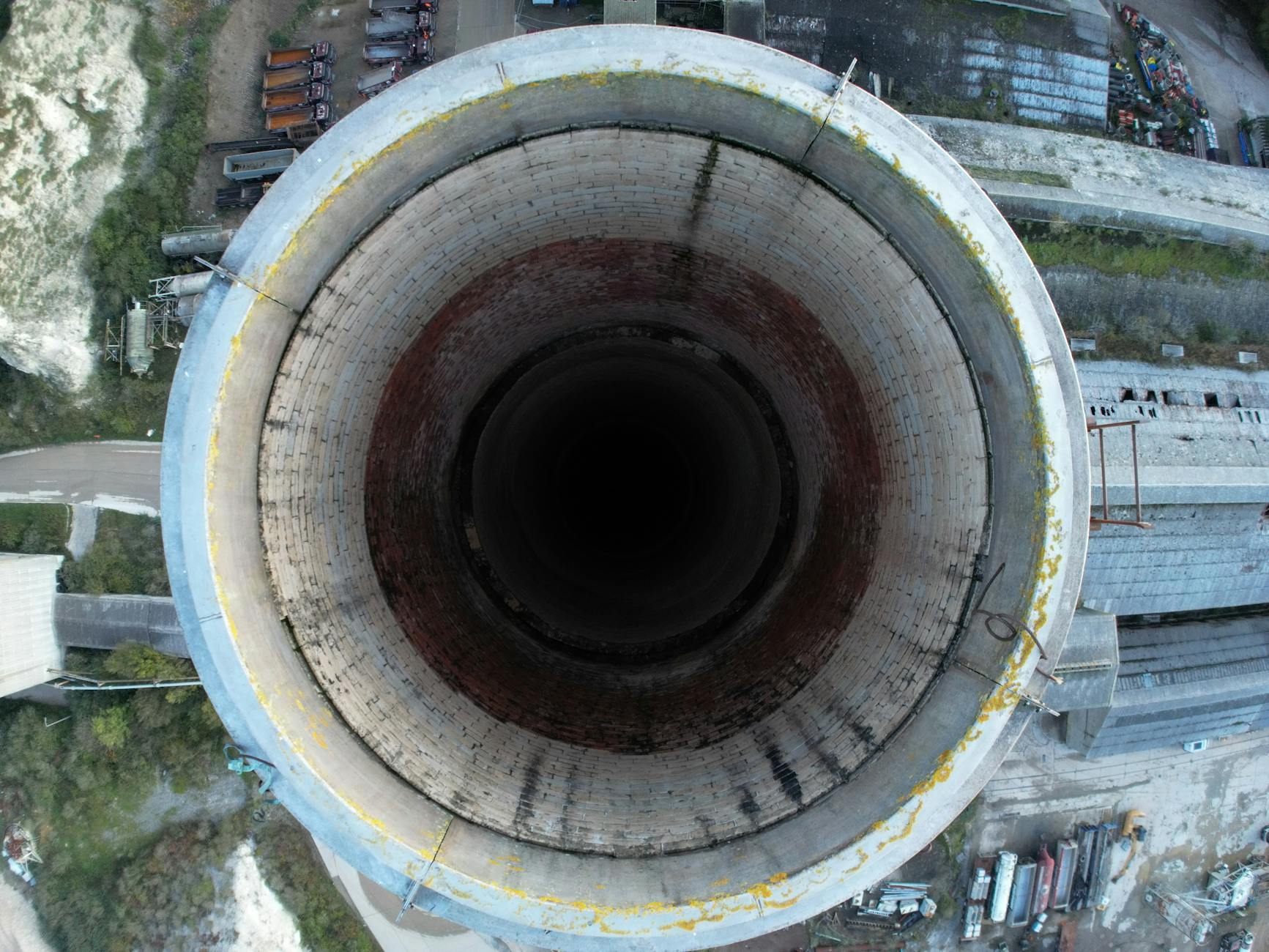

Smart Factories of the Future

The concept of smart factories, enabled by AI technologies, is gaining traction in the UK manufacturing sector. Smart factories utilize AI-driven systems to create interconnected and intelligent production environments. These factories leverage data analytics, Internet of Things (IoT) devices, and AI algorithms to optimize production processes, minimize wastage, and enhance overall operational efficiency. By integrating AI into every facet of manufacturing operations, smart factories are paving the way for a more agile and responsive manufacturing ecosystem.

Predictive Maintenance and Quality Control

AI is revolutionizing maintenance practices in manufacturing by enabling predictive maintenance strategies. By analyzing equipment data in real-time, AI algorithms can predict potential failures before they occur, allowing manufacturers to proactively address maintenance issues and minimize downtime. Moreover, AI-powered quality control systems can detect defects in products with high accuracy, ensuring that only high-quality goods reach the market. This not only improves customer satisfaction but also reduces waste and rework costs for manufacturers.

Supply Chain Optimization

AI is also playing a crucial role in optimizing supply chain processes in the UK manufacturing industry. By analyzing vast amounts of data from suppliers, logistics providers, and customers, AI algorithms can forecast demand, optimize inventory levels, and improve logistics efficiency. This leads to better coordination across the supply chain, reduced lead times, and lower operating costs. AI-powered supply chain management systems enable manufacturers to respond swiftly to market fluctuations and customer demands, giving them a competitive edge in a rapidly evolving industry.

Overcoming Challenges and Embracing Opportunities

While the adoption of AI in UK manufacturing brings about numerous benefits, it also poses challenges such as upskilling the workforce, ensuring data security, and addressing ethical concerns related to AI deployment. However, by investing in training programs, cybersecurity measures, and ethical AI frameworks, manufacturers can overcome these challenges and harness the full potential of AI technologies.

In conclusion, AI is set to revolutionize the UK manufacturing sector in 2025, driving innovations that will transform the industry landscape. From AI-powered robotics and automation to smart factories and predictive maintenance, the integration of AI technologies is reshaping manufacturing processes and paving the way for a more efficient and sustainable future. By embracing these cutting-edge innovations, UK manufacturers can stay ahead of the curve and thrive in the era of Industry 4.0.