- Importance of Robotics Safety Standards

- OSHA Guidelines for Robotics Safety

- ANSI/RIA R15.06-2012 Standard

- ISO 10218-1 and ISO 10218-2 Standards

- CE Marking for Robotics Equipment

- Collaborative Robotics Safety

- Conclusion

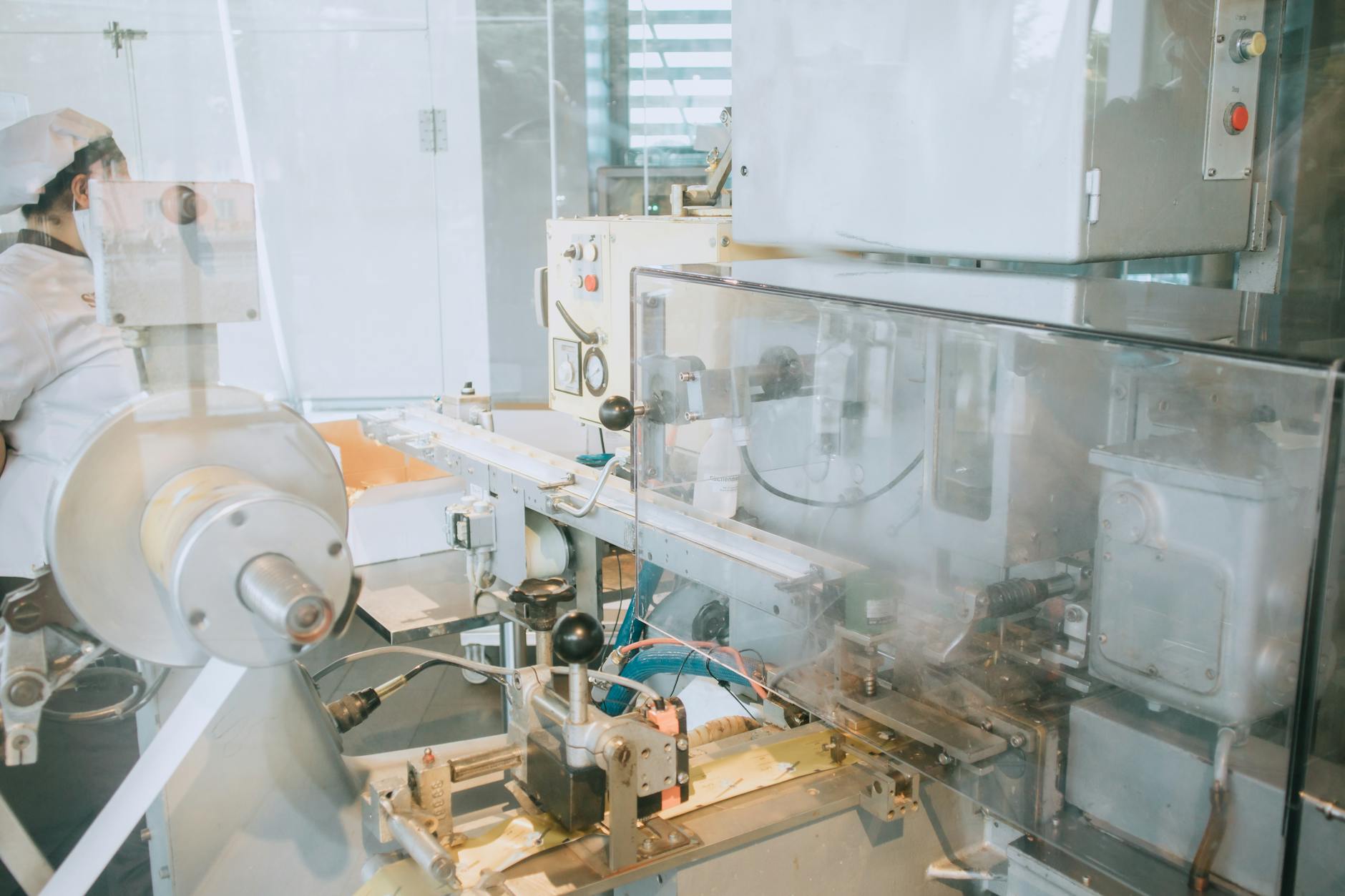

Robotics technology has become increasingly prevalent across various industries, revolutionizing manufacturing processes and boosting efficiency. However, with the integration of robotics in workplaces, it is crucial for manufacturers to prioritize safety standards to ensure the well-being of workers and compliance with regulations. In this article, we will delve into the essential robotics safety standards that manufacturers must be aware of to create a safe working environment and prevent potential accidents.

Importance of Robotics Safety Standards

Robotics safety standards play a pivotal role in safeguarding employees, minimizing risks, and maintaining a productive work environment. These standards are designed to outline specific guidelines and protocols that need to be followed to prevent accidents and injuries associated with robotic operations. By adhering to these safety standards, manufacturers can mitigate potential hazards, safeguard their workforce, and uphold ethical responsibilities.

OSHA Guidelines for Robotics Safety

The Occupational Safety and Health Administration (OSHA) sets forth guidelines and regulations concerning robotics safety in the workplace. Manufacturers must comply with OSHA standards to create a safe working environment for their employees. Some key OSHA guidelines related to robotics safety include risk assessment, training programs, safety protocols, and regular inspections of robotic systems.

ANSI/RIA R15.06-2012 Standard

The American National Standards Institute and the Robotic Industries Association’s (ANSI/RIA) R15.06-2012 standard is a comprehensive document that outlines safety requirements for industrial robots. This standard covers various aspects of robotics safety, including robot design, safeguarding mechanisms, risk assessment, and human-robot collaboration. Manufacturers must familiarize themselves with the ANSI/RIA R15.06-2012 standard and incorporate its guidelines into their robotic systems.

ISO 10218-1 and ISO 10218-2 Standards

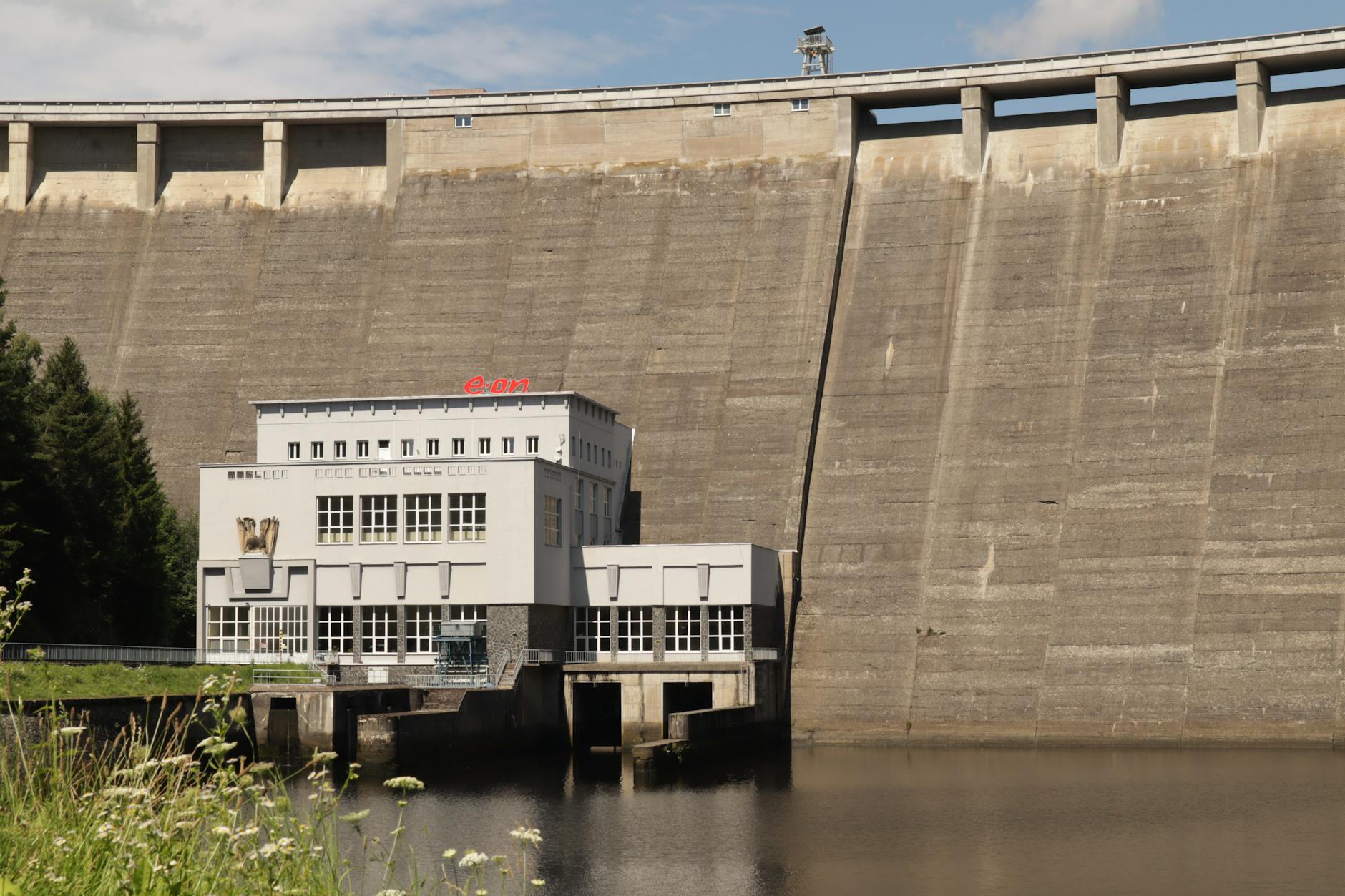

The International Organization for Standardization (ISO) has developed the ISO 10218-1 and ISO 10218-2 standards, which focus on the safety requirements for industrial robots and robot systems. These standards provide guidelines for robot manufacturers, system integrators, and end-users to ensure the safe deployment and operation of robotic systems. By adhering to the ISO 10218 standards, manufacturers can establish a robust framework for robotics safety in their facilities.

CE Marking for Robotics Equipment

In the European Union, the CE marking is mandatory for robotics equipment to demonstrate compliance with safety standards and regulations. Manufacturers must ensure that their robotic systems meet the requirements outlined in the Machinery Directive and other relevant directives to affix the CE marking. By obtaining the CE marking, manufacturers can certify that their robotics equipment adheres to essential safety standards and can be safely used in the European market.

Collaborative Robotics Safety

Collaborative robots, also known as cobots, are designed to work alongside human operators in a shared workspace. Ensuring the safety of collaborative robotics requires adherence to specific safety standards that address the unique challenges posed by human-robot interaction. Manufacturers employing cobots must implement safety measures such as risk assessments, safety training, and built-in safety features to protect workers from potential hazards.

Conclusion

In conclusion, manufacturers must prioritize robotics safety standards to create a safe and secure work environment for their employees. By adhering to regulations such as OSHA guidelines, ANSI/RIA standards, ISO requirements, and CE marking protocols, manufacturers can mitigate risks associated with robotics operations and protect the well-being of workers. Embracing robotics safety standards is not only a legal requirement but also a moral obligation to ensure workplace safety and promote overall efficiency in manufacturing processes. By staying informed and proactive in implementing safety measures, manufacturers can harness the full potential of robotics technology while prioritizing the health and safety of their workforce.